We are owner-builders, working on a timber framed bioshelter in Sterling, New York. Most of the timbers we use are White pine, harvested nearby and milled by local sawyers. However, a lot of our wood is White ash from our own land, as well as long, heavy hardwood timbers salvaged from old barns. We love the look of old, hand-hewn timber!

Freshly cut wood is “green”. It has a very high moisture content and is therefore very easy to work. But the old timbers – maple, ash, beech, red oak, and hickory – are fully dried and very, very hard. Chisel work in dried hardwood is not easy!

We are using 10″ by 10″ timbers for all the posts and most of our beams in our barn, with a few beams that are 8″ by 10″. These are connected, that is to say “joined” with carved-out rectangular openings called mortises that accept carefully cut, squared sections of wood called tenons. As cavities, mortises are challenging to cut because you have to either drill out wood and shape the opening with a mallet and chisel, or gradually make the opening deeper and deeper with chisels alone. Making a mortise in green wood takes some practice, but it is fun. Making a mortise in dry, hard timbers hundreds of years old is difficult, and not much fun!

Harvesting and milling our own timbers. Here I am using my Granberg International Alaskan chain-saw with ripping chain to mill to one of our ash trees doomed by the Emerald Ash borer.

White ash log milled into 25′ slabs and a 10″ by 10″ timber.

Cutting a brace mortise. Our 2″ mortises are laid out 36″ along all outside walls, and at 30″ for all inside walls. This kind of carving is made a lot faster by drilling out the wood first.

Professional timber framers use an electric powered chainsaw mortising tool. It can make accurate mortises very quickly, but they are very expensive. We are doing our best to build out of pocket, with the old Shelter Institute philosophy to “spend money on materials, not tools”. Since I’ve been sawing and slabbing with chainsaws for some years now, I decided to use my chainsaws and jigs to support our timber framing work. And until very recently, we’ve had no power on our property. So it made sense to adapt chainsaw milling to wider application in timber framing.

Typical timber frame joinery: shouldered mortises and tenons, braces and brace mortises, and joists. Drilling out the mortises before chiseling makes the work move much faster.

I cut my tenons with a Granberg International Mini-mill with either of two jigs I’ve made. One jig is a simple redwood 2 x 6 sporting 48″ of Granberg’s Mini-mill track. The second jig is a more complex to allow me to use it to cut shoulders and work with greater precision on the old, hand hewn timbers.

This is my straight jig, very easy to use accurately on square timbers. Also very easy to shim when your timbers are just a little out of square.

Each cheek is cross-cut with a circular saw and cleaned up with a chisel and/or a small plane. I use this check-gauge to test the tenon’s fit.

Here is a similar tenon cut with a chain-saw, cleaned up with Anahiki, chisel, and hand plane.

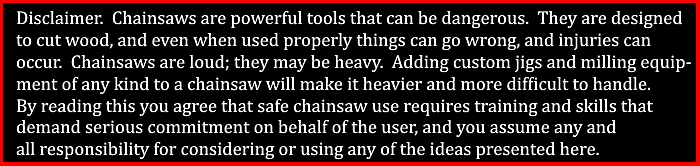

This jig supports a Granberg track for the mini-mill attached to my little Stihl MS-250, rigged with ripping chain. One side of the jig moves, and top and side is easily shimmed and screwed to the timber.

Here is the adjustable jig on an old oak timber we’ll use as a support post. I’m using it to cut a tenon, and you can see the wedges I’ve tapped into place to put the saw square and level.

Careful layout and application with this approach can be very successful. Here’s an old hand hewn beech beam let into a new White pine post. Strap is hooked onto a come-along before pinning.

As noted above, mortising is challenging enough to do well in green wood, but I can tell you from experience it is a brutal job in dried hardwood! (Not to mention the many old cut nails that one finds in old timbers!) My chain-saw mortising machine is based on a large vise mechanism. Vices have tremendous gripping strength since their threads are rectangular in cross section, and therefore they can easily lift and lower a heavy chainsaw – in my case a Shihl 066. My first chain-saw mortising machine was based on a ramp design. It worked, but it was not as stable as I liked. I cut many full mortises with this machine, but over the winter of 2018-2019 I decided to move to a different design.

My first chain-saw mortising machine worked pretty well, but it was fairly heavy and not as stable as I wanted.

My latest chain-saw mortising is based on a scissors lift. It is much smaller than my first version, and it is a lot lighter too. I also like how easily I can adjust the height of my cuts. The heavy-duty vise moves scissors lift in and out, thereby lifting the chain-saw mortising position.

This picture illustrates the position of the saw on my chain-saw mortising machine after the initial plunge cut.

Once I’ve cut out most of the mortise, we’ll clean it up with our chisels.

Trickiest part of this approach is setting up the mortising machine square and level with the timber. Here I am cutting a 2″ by 10″ through mortise in the very same ash timber we milled the previous winter.

North wall of the barn. Note longer braces on exterior wall, and bottom ends of somewhat shorter interior braces.

Help with Timber Framing

Tedd Benson and James Gruber’s Building the Timber Frame House (with awesome illustrations by Jamie Page) is a must-have book for all timber framers. Find it via inter-library loan and you’ll soon plan on getting you own copy.

Will Beemer’s 2016 Learn to Timber Frame, put out by Storey Publishing, is super informative and really helpful to beginners like us.

Eric Sloane’s classic book, A Reverence for Wood is a fun read filled with great information for all woodworkers and builders. Also a great gift for the wood worker in your life.

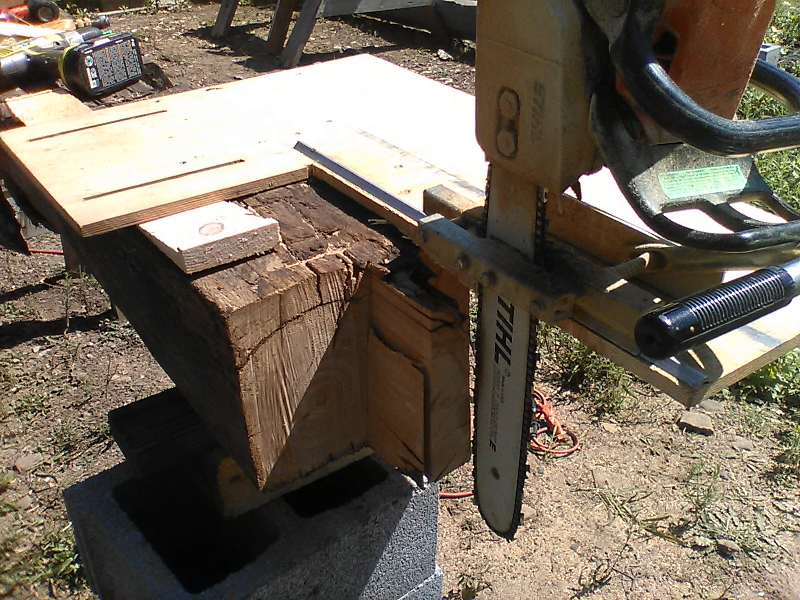

Long ago I was home on vacation from my freshman year at college and came upon Dad’s Fall 1977 issue of Fine Woodworking magazine, Volume 2, Number 2.

Cover featured an article about chain saw lumbering by Robert Sperber called “Chain-saw Lumbering: Get Your Wood Where it Falls.” This really captured my imagination. The main story also includes a history of chainsaw lumber making together with information about modern equipment to help you mill logs with chainsaws.

U.S. Army. 1968. Rigging, Department of the Army Technical Manual TM 5 – 725. Great guide to basic and advance rigging. This book helped me think through our gin pole work.

Helpful links